Have you ever wondered why some cars seem to gleam like mirrors while others look dull and lifeless? The secret often lies in ceramic coating technology. This advanced protection method doesn’t just shield your paint – it transforms how light interacts with your vehicle’s surface.

Ceramic coating creates an incredible visual transformation that goes far beyond basic paint protection. When properly applied, it produces a depth and clarity that makes colors pop and creates that coveted “wet look” that car enthusiasts crave. But how exactly does this technology work its magic?

Understanding ceramic coating’s impact on gloss and shine helps you appreciate why this protection method has revolutionized vehicle care. From the molecular level to the visible results, ceramic coating represents a significant advancement in automotive surface enhancement.

Understanding the Science Behind Ceramic Coating

The magic of ceramic coating starts at the microscopic level. This isn’t just another product that sits on top of your paint – it’s a sophisticated chemical solution that bonds with your vehicle’s clear coat.

What Makes Ceramic Coating Different

Traditional car care products like wax or sealants create a temporary layer on your paint surface. They wear away over time, leaving your paint vulnerable. Ceramic Coating Sterling, VA works differently by forming a permanent chemical bond with the clear coat.

This bonding process creates what scientists call a “cross-linked polymer network.” Think of it like building a microscopic mesh that becomes part of your paint system. This network is incredibly smooth at the molecular level, which directly impacts how light reflects off your vehicle.

The coating fills in tiny imperfections in your clear coat that you can’t see with the naked eye. These microscopic scratches and swirl marks scatter light, making your paint look dull. When ceramic coating fills these imperfections, it creates an ultra-smooth surface that reflects light uniformly.

The Chemical Structure of Nano-Ceramics

Ceramic coating Sterling VA professionals understand that the key lies in silicon dioxide (SiO2) particles. These particles are incredibly small – we’re talking nanometer scale. To put this in perspective, a human hair is about 80,000 nanometers wide.

These tiny particles arrange themselves in a specific pattern when they cure. This arrangement creates a surface that’s both incredibly hard and remarkably smooth. The hardness protects your paint from damage, while the smoothness enhances gloss and shine.

The curing process is crucial to achieving maximum gloss. As the coating cures, the SiO2 particles link together, forming a continuous surface. This process can take several days to complete fully, which is why freshly coated vehicles continue to improve in appearance over time.

The Visual Impact of Ceramic Coating on Vehicle Paint

The transformation that ceramic coating provides isn’t subtle. It creates a dramatic difference in how your vehicle looks under various lighting conditions.

Depth and Clarity Enhancement

One of the most noticeable effects of ceramic coating is the incredible depth it adds to your paint. Dark colors become richer and more vibrant. Light colors gain a clarity that makes them appear almost luminous.

This depth comes from the coating’s ability to create perfectly uniform light reflection. Without ceramic coating, your paint surface has tiny irregularities that scatter light in different directions. This scattering reduces the intensity of reflected light and makes colors appear flat.

Ceramic coating eliminates this scattering by creating an optically perfect surface. Light hits the surface and reflects back at consistent angles, creating that deep, mirror-like appearance that makes people stop and stare.

Light Reflection Properties

The way light interacts with ceramic-coated surfaces is fundamentally different from unprotected paint. Understanding this interaction helps explain why the visual results are so dramatic.

How Light Interacts with Coated Surfaces

When light hits an unprotected paint surface, several things happen simultaneously. Some light penetrates the clear coat and reflects off the color coat underneath. Some light reflects off the clear coat surface. Some light gets scattered by surface imperfections.

This complex interaction creates a mixed reflection that doesn’t produce maximum gloss. Ceramic coating simplifies this process by creating a uniform surface that controls how light behaves.

With ceramic coating, most light reflects off the top surface in a controlled manner. This controlled reflection is what creates that incredible mirror-like finish that makes colors appear so vibrant and deep.

Creating Mirror-Like Finishes

The ultimate goal of ceramic coating application is to create a surface that behaves like a mirror. This doesn’t mean your car will look like chrome, but rather that light reflection will be uniform and intense.

Achieving this mirror-like quality requires more than just applying the coating. The underlying paint must be in perfect condition. Any swirl marks, scratches, or imperfections will show through the coating and reduce the final gloss level.

This is why professional preparation is so important. Speed & Tech Motoring understands that achieving maximum gloss requires meticulous paint correction before coating application.

Types of Gloss Levels Achievable with Ceramic Coating

Not all ceramic coatings produce the same level of gloss. Different formulations and application techniques can create various finish levels to match your preferences.

High Gloss Finishes

The most popular ceramic coating finish is high gloss, which creates that wet, mirror-like appearance. This finish maximizes light reflection and creates the most dramatic visual impact.

High gloss ceramic coatings typically measure 95+ on the gloss meter scale. To put this in perspective, most factory paint finishes measure between 80-90 gloss units. The difference is immediately visible to the human eye.

This level of gloss works particularly well on darker colors like black, navy blue, or deep red. These colors benefit most from enhanced light reflection, creating depth that makes the vehicle appear almost three-dimensional.

Satin and Semi-Gloss Options

Some ceramic coatings offer satin or semi-gloss finishes for those who prefer a more subdued appearance. These finishes still provide excellent protection while creating a different aesthetic.

Satin finishes typically measure 30-60 gloss units, creating a subtle sheen without the mirror-like reflection of high gloss coatings. This option works well for certain vehicle types or personal preferences.

Semi-gloss finishes fall between satin and high gloss, offering moderate reflection with good depth enhancement. These finishes often appeal to owners of work trucks or vehicles used in dusty environments where high gloss might show dirt more easily.

The Application Process and Its Effect on Shine

The way ceramic coating is applied directly impacts the final gloss and shine results. Proper technique is essential for achieving maximum visual enhancement.

Surface Preparation Requirements

Achieving maximum gloss starts long before the ceramic coating touches your paint. Surface preparation is arguably the most important step in the entire process.

The paint surface must be absolutely perfect before coating application. Any defects in the underlying paint will be preserved and potentially magnified by the ceramic coating. This means removing all swirl marks, scratches, water spots, and other imperfections.

Professional paint correction typically involves multiple steps of polishing with progressively finer abrasives. Each step removes scratches left by the previous step while improving overall surface quality.

The final preparation step involves thorough decontamination to remove any oils, waxes, or residues that could interfere with coating adhesion. This preparation ensures the coating can form the strongest possible bond with your clear coat.

Multi-Layer Application Benefits

Many ceramic coatings benefit from multiple layer application. Each layer adds thickness and can enhance the final gloss level.

First Layer Foundation

The first ceramic coating layer focuses on bonding with the clear coat and filling microscopic imperfections. This foundation layer is crucial for overall durability and performance.

The first layer typically doesn’t achieve maximum gloss by itself. It needs time to cure and level before subsequent layers can be applied. This initial layer sets the stage for the final appearance.

Proper curing between layers is essential. Rushing this process can result in reduced gloss and compromised durability. Professional installers understand these timing requirements and plan accordingly.

Building Additional Layers

Additional ceramic coating layers build on the foundation created by the first layer. Each subsequent layer can enhance gloss and depth while adding thickness for improved durability.

The second layer often produces the most noticeable improvement in gloss and visual depth. This layer has a perfectly prepared surface to bond with, allowing it to level perfectly and create maximum optical clarity.

Some high-end ceramic coatings benefit from three or even more layers. However, there’s a point of diminishing returns where additional layers don’t provide significant visual improvement.

Long-term Shine Retention Capabilities

One of ceramic coating’s greatest advantages is its ability to maintain gloss and shine over extended periods. This long-term performance sets it apart from traditional protection methods.

UV Protection and Color Preservation

Ultraviolet radiation is one of paint’s worst enemies. UV rays break down the chemical bonds in paint, causing fading and oxidation that destroys gloss and color intensity.

Ceramic coatings provide excellent UV protection by reflecting and absorbing harmful rays before they can reach your paint. This protection helps preserve both color and gloss over time.

The protection is particularly important for red and other vibrant colors that are especially susceptible to UV damage. Without protection, these colors can fade significantly within just a few years of exposure.

Resistance to Environmental Contaminants

Environmental contaminants like bird droppings, tree sap, and road salt can etch into unprotected paint, creating permanent damage that reduces gloss. Ceramic coating creates a barrier that prevents these contaminants from reaching your paint.

The smooth surface of ceramic coating also makes it much easier to remove contaminants when they do land on your vehicle. This easy cleaning helps maintain maximum gloss with minimal effort.

Water behavior on ceramic-coated surfaces is dramatically different from unprotected paint. The coating’s hydrophobic properties cause water to bead up and roll off, carrying dirt and contaminants away from the surface.

Comparing Ceramic Coating to Traditional Protection Methods

Understanding how ceramic coating compares to traditional methods helps illustrate why it produces superior gloss and shine results.

Ceramic vs Wax Finishes

Traditional carnauba wax has been the gold standard for automotive gloss for decades. However, ceramic coating surpasses wax in both initial gloss and long-term retention.

Fresh carnauba wax can produce impressive gloss levels, often approaching those of ceramic coating. However, this gloss begins diminishing immediately after application and typically lasts only 2-3 months.

Ceramic coating maintains consistent gloss for years, not months. While the initial application requires more investment in time and preparation, the long-term results far exceed what’s possible with wax.

Ceramic vs Paint Sealants

Paint sealants offer better durability than wax but still can’t match ceramic coating’s performance. Most sealants last 4-6 months before needing reapplication.

Durability Differences

The durability difference between ceramic coating and traditional sealants is dramatic. While sealants gradually wear away, properly applied ceramic coating can last 2-5 years or more.

This durability difference directly impacts gloss retention. Sealants lose their gloss-enhancing properties as they wear away, requiring frequent reapplication to maintain appearance.

Ceramic coating Sterling VA applications maintain their gloss-enhancing properties throughout their lifespan because they don’t wear away like traditional products.

Maintenance Requirements

Ceramic-coated vehicles require less frequent maintenance than those protected with traditional methods. The durable nature of the coating means longer intervals between major maintenance sessions.

However, ceramic coating isn’t maintenance-free. Regular washing and periodic inspections are still necessary to maintain maximum appearance and performance.

The maintenance that is required is typically easier and less time-consuming than maintaining wax or sealant protection. The coating’s smooth surface releases dirt more easily, making washing more efficient.

Factors That Affect Ceramic Coating Performance

Several factors influence how well ceramic coating enhances gloss and shine. Understanding these factors helps set realistic expectations.

Paint Condition and Preparation

The condition of your paint before ceramic coating application directly impacts the final results. Perfect paint preparation produces perfect results, while compromised preparation limits the coating’s potential.

Single-stage paints, common on older vehicles, may not achieve the same gloss levels as modern clear coat finishes. The coating can still provide significant improvement, but the results may be more subtle.

Paint thickness also affects results. Thin paint may not allow for aggressive correction, limiting the perfection level achievable before coating application.

Environmental Conditions During Application

Temperature, humidity, and air quality during application affect coating performance. Ideal conditions produce the best results, while challenging conditions can compromise the final appearance.

High humidity can interfere with proper curing, potentially reducing gloss levels. Extreme temperatures, either hot or cold, can affect how the coating levels and bonds with the paint surface.

Professional installation facilities control these environmental factors to ensure consistent, optimal results regardless of outside conditions.

Common Misconceptions About Ceramic Coating Gloss

Several misconceptions exist about ceramic coating’s gloss-enhancing properties. Understanding the reality helps set appropriate expectations.

Instant Results Expectations

Some people expect ceramic coating to produce maximum gloss immediately after application. While results are visible immediately, the coating continues to improve over several days as it fully cures.

The curing process allows the coating to level perfectly and achieve maximum optical clarity. This is why freshly coated vehicles often look even better after a week than they do immediately after application.

Patience during this curing period is important. Avoiding washing or contamination during the first few days allows the coating to achieve its full potential.

Maintenance-Free Assumptions

Another common misconception is that ceramic coating eliminates all maintenance requirements. While coating reduces maintenance needs, it doesn’t eliminate them entirely.

Regular washing is still necessary to maintain maximum gloss. However, the washing process is typically easier and more effective on coated surfaces.

Periodic professional maintenance may be needed to address any issues and maintain optimal performance throughout the coating’s lifespan.

Professional vs DIY Application Results

The application method significantly impacts the final gloss and shine results. Professional and DIY applications often produce very different outcomes.

Equipment and Technique Differences

Professional installers have access to specialized equipment and techniques that aren’t available to DIY enthusiasts. This equipment helps ensure optimal application conditions and consistent results.

Professional-grade coatings often have different formulations than consumer products. These formulations may offer better gloss enhancement and longer durability.

The experience factor is also crucial. Professional installers have applied thousands of coatings and understand the nuances that affect final results.

Quality Control Standards

Professional installations typically include quality control measures that ensure consistent results. These measures include detailed inspection and correction of any application issues.

Speed & Tech Motoring maintains strict quality standards that ensure every ceramic coating application achieves maximum gloss potential. This attention to detail makes a significant difference in final results.

Professional warranties also provide peace of mind that DIY applications can’t match. If issues arise, professional installers stand behind their work.

Maintaining Maximum Gloss After Application

Proper maintenance after ceramic coating application is essential for maintaining maximum gloss and shine throughout the coating’s lifespan.

Proper Washing Techniques

Washing technique becomes even more important on ceramic-coated vehicles. While the coating makes washing easier, using proper techniques maintains optimal appearance.

The two-bucket method remains the gold standard for washing coated vehicles. One bucket contains soapy water, while the other contains clean rinse water. This method prevents dirt from being redistributed across the paint surface.

Microfiber wash mitts work better than traditional towels or sponges on ceramic-coated surfaces. The microfiber’s structure is less likely to cause marring while effectively removing contaminants.

Speed & Tech Motoring Serving the Loudoun Valley Estates, Community and Beyond in Sterling VA

Speed & Tech Motoring is dedicated to serving the diverse needs of the local community of Sterling VA, including individuals residing in neighborhood like Loudoun Valley Estates. With its convenient location and major intersections like ” Old Ox Rd & Puskas Dr and Old Ox Rd & Carters School Rd (coordinates: 38.96270340541798, -77.50384570374446), we offer window tinting services.

Get Window Tinting Services at Loudoun Valley Estates Now

Navigate from Loudoun Valley Estates to Speed & Tech Motoring Now

How Ceramic Coating Enhances Gloss and Shine: Key Data & Insights

- Gloss Improvement Measured by Gloss Meter:

- Typical untreated automotive paint gloss level: ~60 GU (Gloss Units)

- After professional ceramic coating application: 85-95 GU (up to 58% increase in gloss)

- Maintains >80 GU gloss for 2-5 years with proper care (Chemical Guys, 2025)

- Durability & Hydrophobic Performance:

- Ceramic coatings form a semi-permanent bond with paint via SiO₂ nanoparticles creating a glass-like layer

- Hydrophobicity (water contact angle) starts near 110° and gradually declines but remains >90° after 1500 hours of accelerated weather testing (Bob Moses Ceramic Coating, 2021)

- Water beading and dirt repellency reduce cleaning frequency by up to 50%

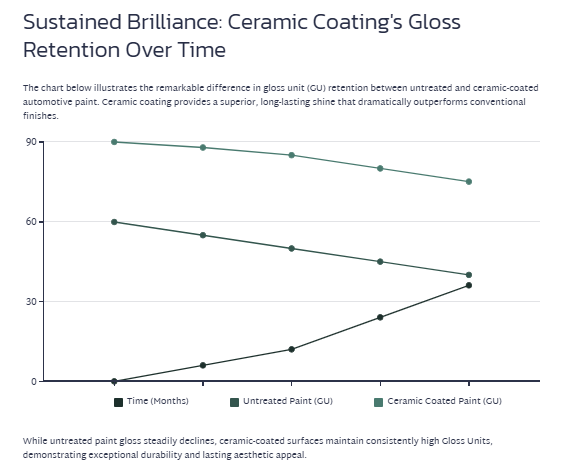

- Gloss Retention Over Time:

- Without maintenance, gloss can drop from ~90% to below 60% within 1-2 years (The Detail Doc, 2025)

- Regular maintenance (pH-balanced washes + ceramic boosters) extends gloss life and shine retention

- Visual Impact:

Ceramic coatings fill microscopic paint imperfections, creating a smoother surface that reflects light more uniformly, resulting in a mirror-like finish (Authentic Details, 2025)

While ceramic coating reduces maintenance needs, periodic professional maintenance helps maintain optimal performance and appearance.

Annual inspections can identify any issues early and address them before they affect appearance. These inspections might reveal areas that need attention or additional protection.

Some ceramic coatings benefit from periodic “booster” applications that refresh the surface and maintain maximum hydrophobic properties. These boosters help maintain the coating’s gloss-enhancing capabilities.

Ceramic coating represents a revolutionary advancement in automotive surface protection and enhancement. Its ability to create incredible gloss and shine while providing long-term durability makes it an attractive option for vehicle owners who demand the best appearance.

The science behind ceramic coating’s gloss enhancement is fascinating and complex. From the molecular level interactions to the visible results, every aspect works together to create that coveted mirror-like finish that makes vehicles look their absolute best.

While ceramic coating requires a significant initial investment in proper application, the long-term benefits in appearance and protection make it worthwhile for those who appreciate automotive excellence. The combination of enhanced gloss, superior durability, and reduced maintenance requirements creates value that extends far beyond the initial application.

Frequently Asked Questions

How long does it take for ceramic coating to reach maximum gloss?

Ceramic coating continues to improve in appearance for 2-7 days after application as it fully cures. While immediate results are visible, maximum gloss is typically achieved within the first week of curing.

Can ceramic coating be applied over existing wax or sealant?

No, ceramic coating requires a completely clean surface free of all waxes, sealants, and oils. Any existing protection must be completely removed before ceramic coating application to ensure proper bonding.

Will ceramic coating make scratches and swirl marks disappear?

Ceramic coating will not remove existing scratches or swirl marks. These defects must be corrected through paint polishing before coating application. The coating will preserve whatever paint condition exists at the time of application.

How often should ceramic-coated vehicles be washed?

Ceramic-coated vehicles should be washed when they appear dirty, typically every 2-3 weeks under normal conditions. The coating makes washing easier and more effective, but regular cleaning is still necessary to maintain optimal appearance.

Does ceramic coating work equally well on all paint colors?

Ceramic coating enhances all paint colors, but the visual impact is most dramatic on darker colors like black, navy blue, and deep red. Lighter colors also benefit significantly, though the enhancement may be more subtle to the untrained eye.